We have undergone many iterations throughout the semester.Let us show you all the intermediaries!

Forewords

Our project was divided into four phases, each of them called Sprints. At each of these sprints, with the exception of Sprint 2, we had an iteratively improved integrated prototype that could be play-tested. It was exciting to see, at the end of each sprints, how much we have come from the beginning!

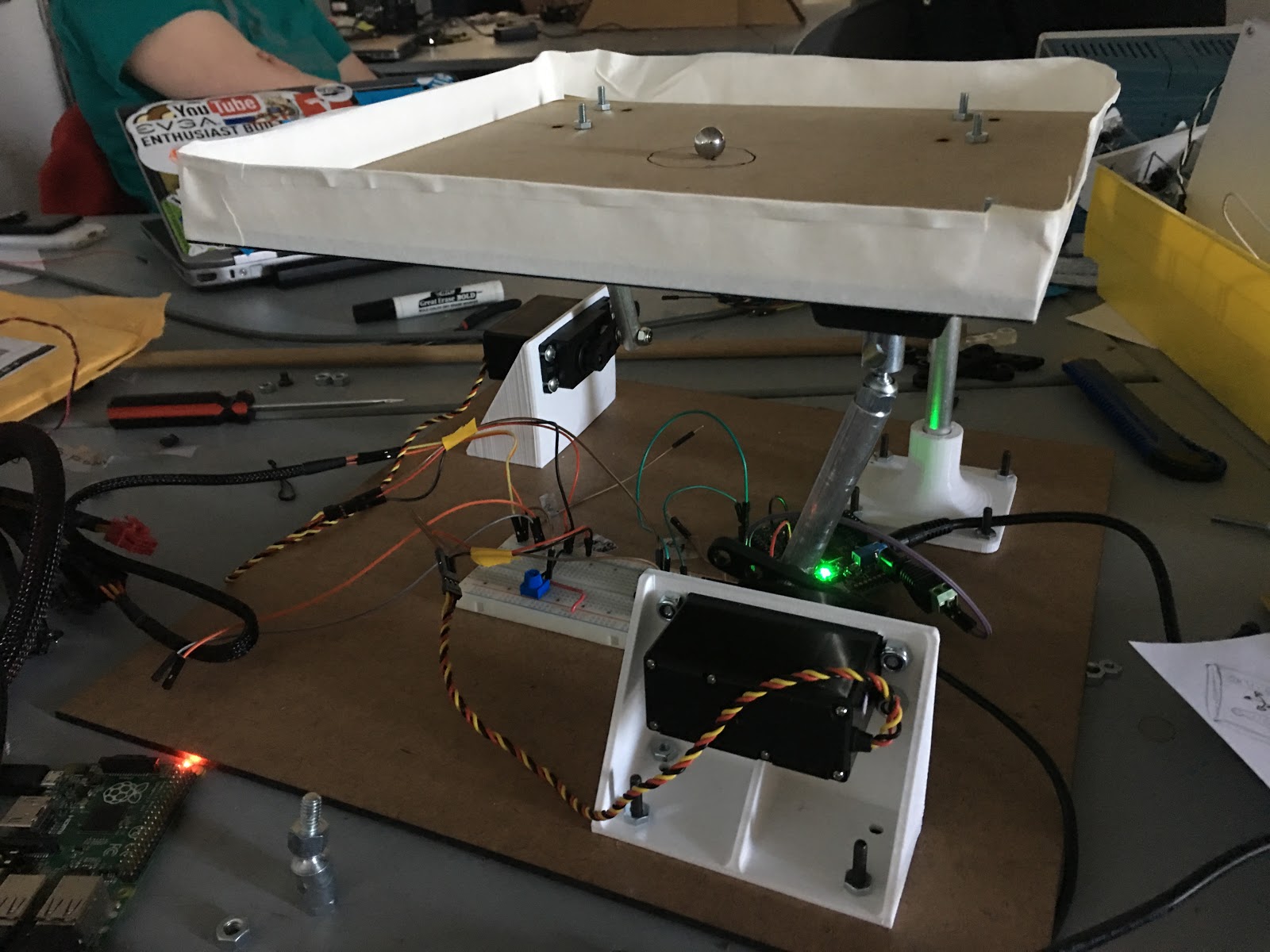

Sprint 1

At the end of Sprint 1, we had a small-scale board designed and built. The

aims of Sprint 1 were to, connect with the RasPi to communicate with the

Wii balance board, and to design and test our initial mechatronic

system for the tilt mechanism.

Mechanically, the biggest insight of this sprint was with the ball joints used in mounting

the tilting board to the base. We were using ball joints for all 3 connections, and this

left an extra degree of freedom allowing the tilting board to spin rather than purely tilt.

This made us realize we needed to use a U-joint in the center mount to prevent the rotation.

Electrically, the challenge was to give the servos 5V, when the signal from the PIC was only

3.3V. We developed the logic converters shown in the Electrical

Design section during this sprint.

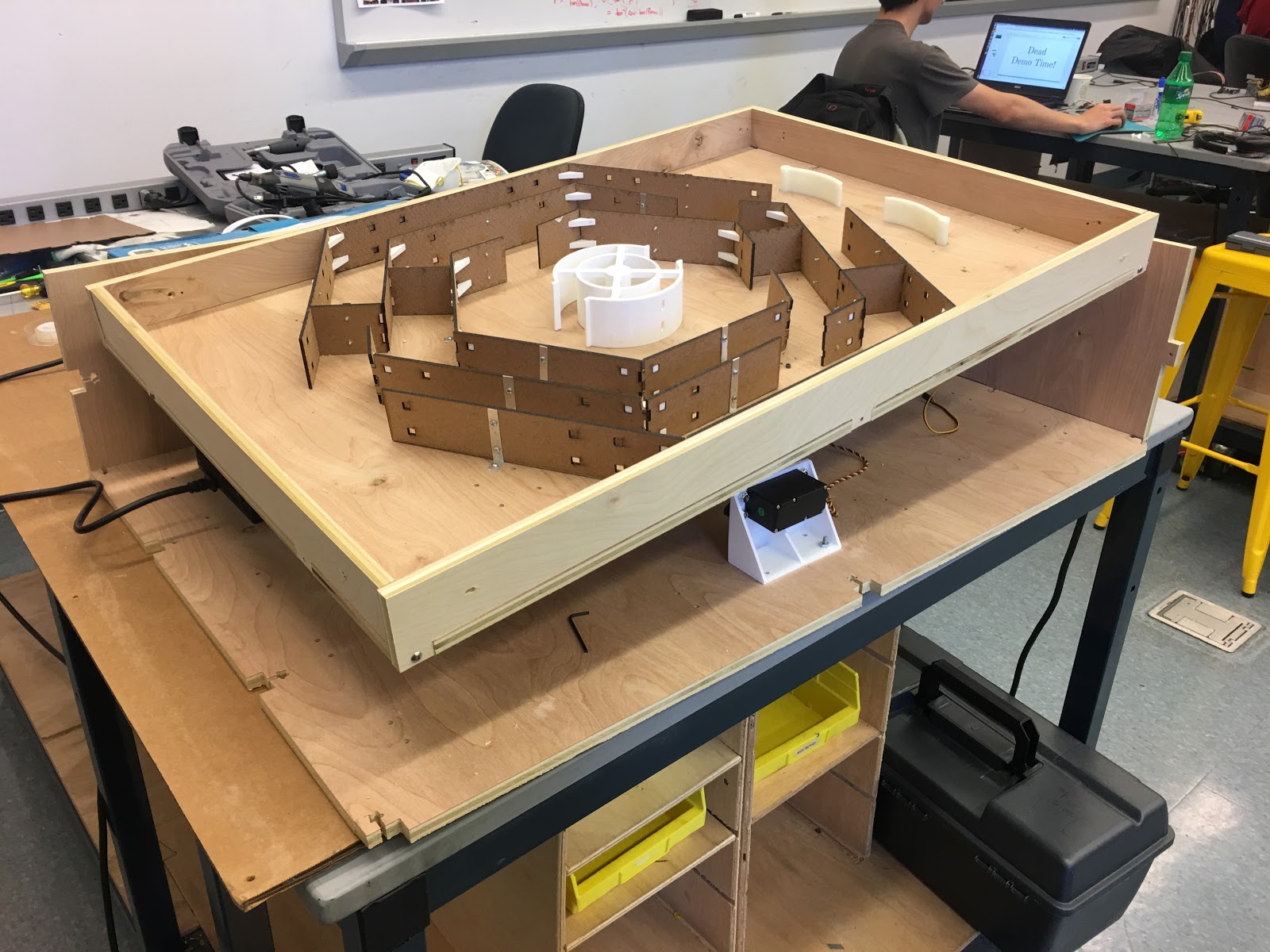

Sprint 2

Sprint 2 was a lot of experimentation and growth. By the end of this sprint, we had defined

our MVP, built a full-scale model of the game, and had tested

several actuation and data collection methods.

During the sprint, we Shopbotted our first life-sized hull; due to

lack of foresight and changing designs, the panels had to be postprocessed nonetheless to

accomodate our central maze and the spinner.

We also implemented our initial layout of the FSM, with which we could control flippers and

the central spinner. We also had the coin mechanism working, and mostly accomplished lots of

tasks in the way. A lot of work was spent on debugging; the linear actuator was

malfunctioning, for instance, as well as the accelerometer library. After a period of

efforts in vain, we prioritized on the integrated product, so both of these efforts were

tabled.

Overall, we determined our MVP and were well on our way to making a complete game.

Sprint 3

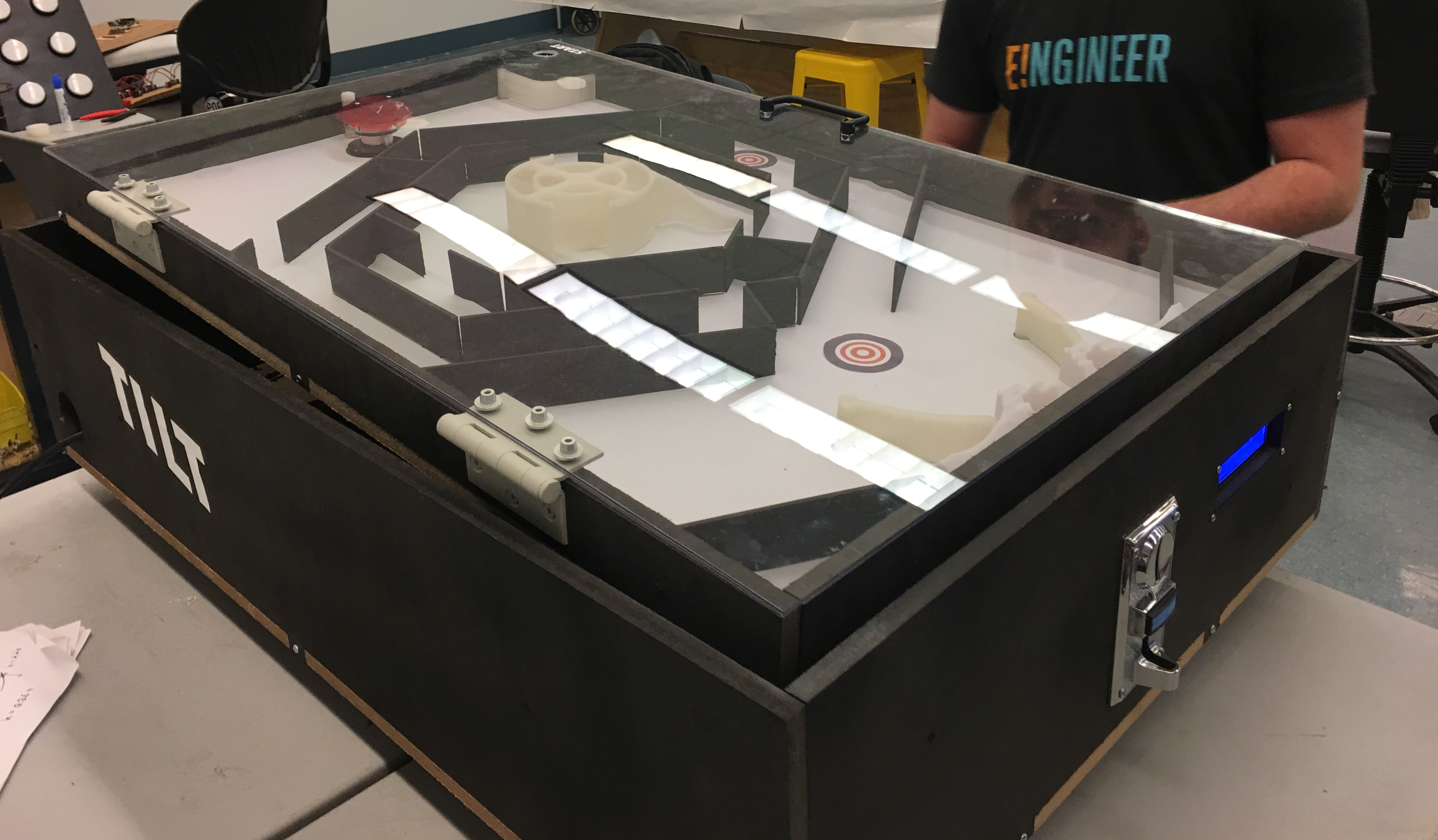

This sprint marked our Minimum Viable Game.

Mechanically, we successfully made the game

robust with a U-joint designed for a car steering rack. This prevented twisting and made it

substantially less likely that an errant 4th grader would damage the system. We additionally

solved our issues with the center spinner clearance that we were having in Sprint 2 by

increasing the gap between the walls to allow the ball to easily travel between them,

lengthening the connection to prevent interference between the walls and the game surface,

and integrating the blocking outcrop into our 3D printed part, rather than having a wood

flap that fell off during testing.

Electrically, we wired improved the strength of the electromagnets by using

a boost

converter to step up the 12V power supply potential to 30V. However, we were actuating this

signal directly with a simple push-button. Moving forward, we would need to use mosfets to

electronically control the actuation of the electromagnets This allowed us to design the

electrical system, even without being integrated in the code yet. We tested the pop bumper,

so that we could integrate it in the next sprint, and wired up buttons for control as well,

and started planning for moving our circuit to proto-boards.

For Software, we updated the state machine to be easily extensible (this

turned out to be

extremely helpful later on), and had all the game logic and active element control

implemented and tested. This was also the sprint where we got the LCD screen with

instructions working.

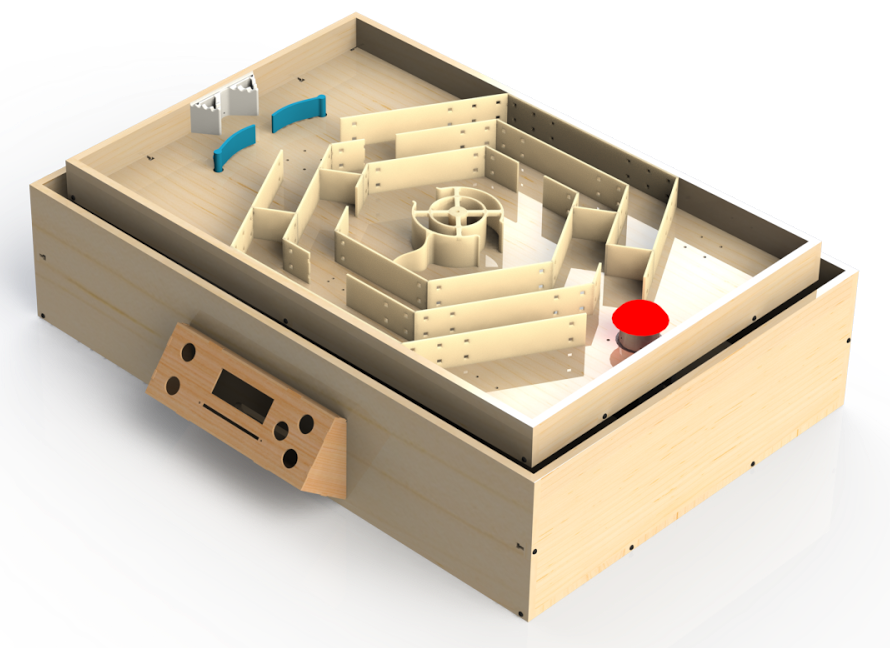

Sprint 4

The final 2 weeks of our project were mostly dedicated to polish and

robustness. We improved

electrical connections, worked out software bugs, recut panels, painted the the game, and

more. We took all the design insight we had learned prior and cut an entire set on new body

panels out of MDF. We chose MDF over plywood this time around as it was less subject to warp

(our 1st game area was a little askew).

The hardboard maze was designed to slot directly into the game surface as a press fit rather

than needing to be fastened down by screws, as was the case with the first design. Lastly, a

coat of black paint was applied to all the exposed surfaces and a layer of while vinyl was

used to cover the countersunk screws holding in various components into the game area.

When we revisited the Raspberry Pi, it unexpectedly broke down, so we had to reconfigure

another one. A lot of effort was put into making the startup sequence, as well as the

following execution sequence, robust and reliable, so that the game would be a plug-and-play

experience.

Final Game

After all these sprints, we finally arrived at our final product! Click on the link to get started on the systems overview, starting from mechanical.